In this article we’ll review the .030 vs. .035 Flux Core Wire and see which one comes out on top!

In a task which concerns welding, it isn’t easy to find the wire with the right size for you. Thus, here we have made a comparison between .030 and .035 Flux Core Wire so that you can purchase the straight flux core wire according to your work.

What Is A .030 Flux Core Wire?

As the name suggests, .030 Flux Core Wire is a wire used in the welding process, which has a core made of flux. The number .030 used in the name of the product is to specify the welding rod diameter.

The .030 Flux Core Wire requires less amperage since it is thin and can only work with thin metal sheets. .030 Flux Core Wire faces troubles during welding thick metal sheets. This flux core wire doesn’t require any external gas containers.

When To Use .030 Flux Core Wire?

.030 Flux Core Wire is the best option if you are working with thin material and light metals. This wire can be used when you don’t require welding gas in your process or don’t have any welding gas.

Pros & Cons of .030 Flux Core Wire

What Is .035 Flux Core Wire?

Just like .030 Flux Core Wire, 0.35 Flux Core Wire is a welding wire. It is equipped with flux in the center, which can furnish a filler metal when melted for a smooth welding job. The number .035 used in the name of the product specifies the welding rod diameter.

.035 Flux Core Wire needs a high degree of amperage because it’s thick, and it burns at a very high temperature and gives a better and deeper piercing performance.

When to Use .035 Flux Core Wire?

To use a .035 Flux Core Wire, you must decrease the wire speed and increase the voltage. It works flawlessly on thick sheets of metal. You can use it both with and without gas. It splatters in case you are not using gas, but it works perfectly with gas.

Pros & Cons of .035 Flux Core Wire

Main Differences between .030 Flux Core Wire & .035 Flux Core Wire

- The differences between .030 and .035 flux core wire are as follows:

- The welding range of .030 Flux core wire is around 50 to 150 Amp approx, and on .035, it is from 75 to 200 Amp approx.

- The voltage range of .030 wire is around 15 to 17 volts, and for .035 wire, it is from 15-18 volts approx.

- The wire feed speed range of .030 wire is 80 to 445 inches per minute and on .035 wire is 70 to 305 inches per minute.

- 0.30 wire is suitable for piercing thin metal sheets, and 0.35 is more suitable for thick metal sheets, which are 1/4 inches thick.

Conclusion & Recommendation

This comparison can’t be clearly stated, which wire is better since you choose the wire depending on the metal you’ll be welding and the machine you’ll use. It can’t be clearly stated which wire is better.

For beginners or a general welding job, .030 is ideal for heavy metals, .035 wire.

Video

Video of .030 flux core wire

https://youtu.be/2a-kU88HXHg

Video of .035 flux core wire

https://youtu.be/djv0Fwzm3X8

Bestseller List

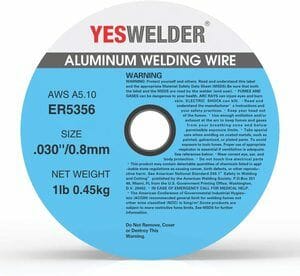

Best .030 flux core wire

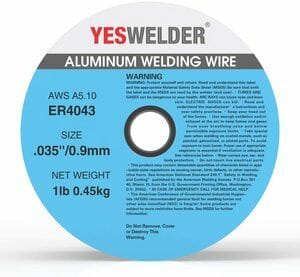

Best .035 flux core wire

FAQs

1. Which is better .030 or .035 flux core wire?

To weld thicker metals, use 035 welding wires, while to weld thinner metals, use 030 welding wires. The thicker the rod, the more amp it will use and, thus, it will burn hotter and go deeper.

2. Is thicker welding wire better?

Often, the slower-feeding thicker wires are used. An increase in current causes irregular arcs and spatter deposition on the weld. To improve your power, you need to utilize thicker wires.

3. What size flux core wire should I use?

030-inch is a solid pick for welding a wide range of metal thicknesses. Use 035-inch (or 045-inch) wire for welding thicker material at greater total heat levels.

4. Does flux core wire go bad?

The flux core wire is not solid; therefore, the water can enter the wire. Flux core wires are damaged if exposed to dampness for a long time. If you take good care of your wire, it should remain serviceable.

5. Can you use a .035 tip with .030 wire?

Using 035 wire with a 030 tip wouldn't work because the wire is too little. It is called a "contact tip", and this wire is activated by power for welding.