There are a lot of ways to join two materials together.

In some cases, adhesives like glues or cements might work.

Fasteners like staples or rivets or screws or nails can create a pretty strong bond. However, when you are trying to join metal parts together, none of the above is likely to work.

To adequately join metal parts together you need to solder, braze or weld the two metals - all processes based on heat.

Many people get confused as to the differences between these processes.

That’s pretty natural since they do have a lot in common. But they serve for different types of metals and applications and involve different skills, gear and equipment.

Common Elements Of Welding, Soldering, and Brazing

Welding, soldering and brazing are all methods used to join metals together.

While each method is different, they all have many things in common.

Cleaning: Whatever method you use, it is important to start with two clean pieces of metal. If they are not cleaned properly, the solder, braze or weld will not hold and can result in gas or liquid leaks flowing through a pipe, or a break in the joint which means you have a structural defect.

Proper Gear: All three methods require the operator to wear gloves and protective gear to protect them from getting metal fragments stuck in their hands and/or fire and flames creating molten metal that can drip on exposed skin.

Heat: Most importantly, all these methods involve heating either the parts to be joined, or a filler material, or both. When sufficiently heated the materials are joined in a bond strong enough to serve a particular purpose.

What Is Soldering?

Soldering joins two metals together by applying solder to the pipe or metal sections.

A soldering iron melts the solder - a filler metal - at low temperatures (up to 450° C).

The solder is laid right where the materials will be joined. Solder may be a solid in the form of a wire, but can also come in a paste form, called flux.

In this case, only the solder is heated, not the work pieces themselves.

Soldering’s most common use is to join electrical contacts. It is also used in plumbing and metalwork requiring low temperatures. It is useful for various metals, including gold, silver, copper, brass, and iron.

Soldering Equipment

Two Methods Of Soldering

Iron soldering is the oldest and simplest and involves a soldering iron with a copper tip, which stores and transfers heat to the joint or seam.

Wave soldering is most often used in electronic component and printed circuit board manufacturing. Continuously circulating waves of solder are lifted into contact with the joints or seams of the metal.

The process is very high speed and is often automated in a wave solder machine that can flux, preheat, solder and remove flux residue on a continuous conveyor.

The soldering process involves prepping the metal, heating the metal ends, melting solder in the joint or seam, cleaning the metal and cooling the metal.

Soldering has a moderate level of difficulty and micro soldering can be very challenging.

Advantages of Soldering:

Disadvantages of Soldering:

What Is Brazing?

Brazing is similar to soldering in that both are joining processes that use a combination of heat, filler metal and a flux to join metals together.

In brazing, you apply a flux solution between the filler metal and the pieces of metal to be joined together and heated.

The difference between soldering and brazing is that brazing involves temperatures up to 840°F/450°C, while soldering uses filler metal heated at temperatures below that.

Unlike welding, both brazing and soldering involve heating the filler metal at temperatures below the melting temperature of the metal work pieces being joined together.

Brazing is often used for very thin metals like aluminum. Higher temperatures could cause damage or destruction to these metals. It’s also useful difficult-to-access joints that can’t be soldered. Most ferrous metals and many carbides and cermets can be joined by brazing.

Equipment For Brazing

Methods Of Brazing

Torch brazing uses oxyfuel gas like acetylene, propane or even city gas and a gas torch.

Furnace brazing involves parts that are preloaded with filler metals and flux and the put in a furnace. This process is normally used in factories for automated production.

Dip brazing involves a heated chemical bath which is both the fluxing agent and the heat source. Pre-assembled parts with pre-applied filler material are dipped into the bath. This process is most commonly used with aluminum assemblies.

Induction brazing uses tongs or clamps holding the metal pieces to inductor coils to create an electrical current around a pre-assembled, pre-fluxed part that has been preloaded with filler material.

This process is used when part of the assembly would be adversely affected by heat Induction allows the metal piece to be selectively heated by the coil.

Brazing requires a moderate amount of skill.

Advantages Of Brazing

Disadvantages of Brazing

What Is Welding

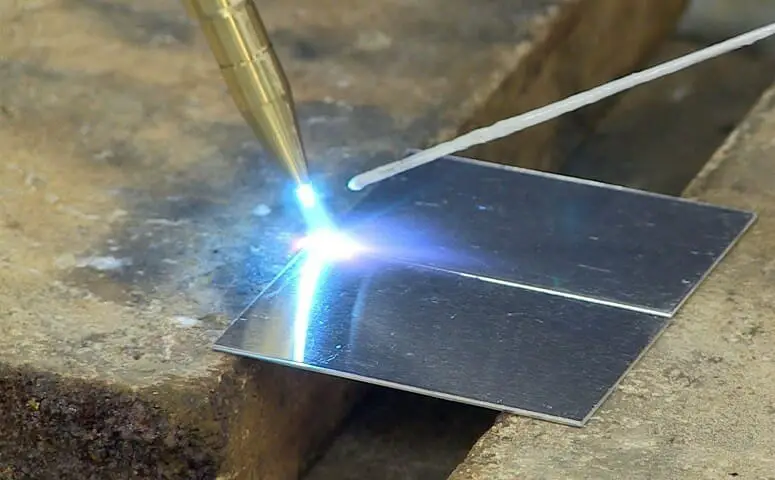

Welding uses higher temperatures to heat the filler rods and edges of the base work pieces to create a strong, bonded weld between the metals.

Unlike soldering or brazing, welding heats the base metal pieces to their melting point to fuse or weld them together. Welding typically involves temperatures over 840° F (450° C).

Welding is commonly used in industrial processes, the building trades, automotive, shipbuilding, aircraft and heavy equipment construction, pipe lines, railroads, tanks and vessels. Think of a bridge made of metal. Welding joins together the pieces of metal in thousands of joints or seams.

There are several methods of welding such as Plasma Arc welding, MIG welding, TIG welding, Gas Welding, Laser welding. There is even underwater welding, used mainly for maritime applications!

Required Welding Equipment

For Gas Welding

For Arc Welding

Appropriate protective gear is also essential, considering the extremely high temperatures involved as well as the debris that may be generated.

Some welding processes involve gases pumped into the welding torch or gun by an electric power source. Others involve simply a highly-heated rod.

The flame or heated rod is applied directly to the base metal pieces. The edges are melted and in some applications, a filler wire is fed into the joint or seam to fuse or weld the pieces together as the torch or gun is moved down the joint or seam.

While there is a variety of difficulty levels within the various types of welding, it is generally considered more difficult than soldering or brazing. This is because of the extremely high temperatures and the range of metals being welded.

Advantages of Welding

Disadvantages Of Welding

Welding vs Brazing vs Soldering Explainer Video

FAQs

What is the difference between welding, brazing and, soldering?

Brazing and soldering techniques are similar in that a filler medal is melted to join the metals together. Welding actually melts the two pieces together to join them together and therefore create a stronger bond. Brazing and soldering are easier to accomplish and require less training to do.

What is stronger welding, brazing, or soldering?

Welding is stronger than both brazing and soldering.

What metals can be brazed?

Popular metals to be brazed include

- aluminum

- copper

- stainless steel

- precious metals (gold, silver)

- titanium

- brass

Can you braze with a propane torch?

Yes you can braze with a propane torch, but you will need more equipment to properly regulate the late. Since propane torches aren't very hot you'll have to make sure to minimize heat loss of the object(s) you are brazing. Here is a good video to show you how:

What is brazing used for? Why is brazing better than welding?

Brazing is good in situations where the pieces that need to be joined are very small or thin. Welding isn't a good choice in this case because it may ruin the structure of the objects.

Why are bike frames brazed instead of welded?

Bike frames are brazed instead of welded because they are very thin and welding them may actually weaken or ruin the frame. Brazing is a good use in this case since you'll have more control of the joins with the lower temperature that is involved.

Conclusion

As with any process, the decision whether to use soldering, brazing or welding comes down to the application. The type of metals - or even non-metallic materials, the purpose of the joint, and the size of the structure all dictate which process you will use.

The key difference between the processes is the amount of heat used, and all of these factors play into what process fits each case.