Welding is the process of joining and cutting metals or thermoplastic materials using high heat to melt two parts together before allowing them to cool and merge. Welding is quite different from other lower temperature joining techniques like soldering, which never melts the base metal. Besides melting the base metal, filler metals are added to the joint to create the weld pool that cools when forming the joint. Welding can be done using a wide range of energy sources like electricity, gas flame, or a laser, among other sources.

Welding is one of the leading techniques in the manufacturing industry that generates a lot of fumes and toxic chemicals. Therefore, it's crucial to know the effects of welding on your surroundings and what can be done to make welding eco-friendly. After all, most governments and NGOs are advocating for industries to go green. So, here five ways to make this process eco-friendly:

5 Methods to Make Welding Eco-Friendly

1. Use Different Welding Techniques

Instead of using the traditional welding method, which releases a lot of harmful chemicals into the atmosphere, you can use an eco-friendly welding technique. There are numerous sustainable and new welding techniques that reduce environmental, manufacturing, and operational costs while lowering the carbon footprint. Some of these methods are:

Friction Welding

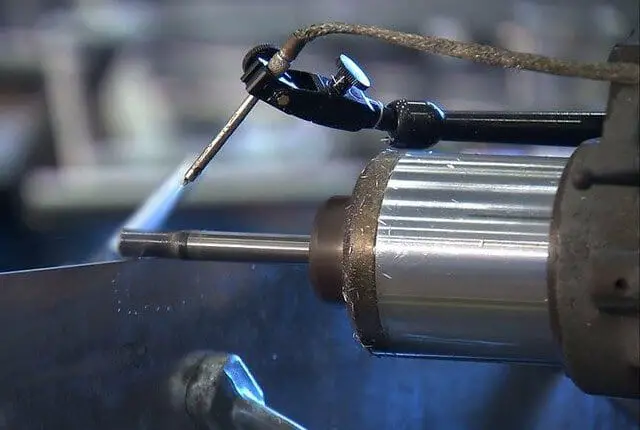

As the name suggests, this welding process involves the use of frictional force. Frictional welding is a solid-state welding process that uses mechanical friction to generate heat between the workpieces and the rotating tool. During this process, the materials heat up to the point where they can merge as friction builds up. Friction welding is an eco-friendly welding process as it takes away the need for flux and allows you to generate merge or cut metal using the needed amount of energy. Friction welding also helps you lower your carbon footprint and produce clean air.

And since no melting occurs, this method is considered to be a solid-state welding method, just like forge welding and not a fusion welding technique. Frictional welding is used with thermoplastics and metals in a wide range of automotive and aviation applications, says Eco Peanut. Friction welding can also work on wood.

Vacuum Soldering

Vacuum welding is one of the most highly recommended welding processes because it's very environment-friendly. And unlike the traditional soldering process, which is a chemical-heave process that releases a lot of dangerous chemicals into the air, vacuum soldering uses hydrogen. According to Your Energy Blog, hydrogen produces the same amount of energy without polluting the environment.

Diffusive Welding

Diffusive welding combines heat and pressure to produce extremely high-quality joints. It removes the need for flux, making it an eco-friendly, sustainable welding process. Diffusive welding is a simple welding method that delivers impressive results. However, this process is sometimes not feasible as it is a lengthier process which can be costly for large-scale welding.

2. Use Sustainable Tools

When we say sustainable tools, we mean high-quality tools that don't wear out or breakdown easily. Remember, low-cost tools are made using low-quality materials that are not repairable and wear out quickly. Therefore, you might end up with numerous damaged tools that need to be disposed of when you buy low-quality welding tools. Instead of purchasing these cheap tools, you should go for high-quality material that maintains heat balance with long service life and reduces raw material consumption.

3. Recycling

Recycling is one of the easiest and most popular methods of reducing environmental costs and becoming eco-friendly. In fact, the first step to sustainable welding is recycling all the scrap material and lowering the production waste. For example, you can return all the metal shavings to the manufacturers for recycling. Before returning them to the manufacturers, you should separate the chips from the lubricants needed in the production process using a centrifuge. The lubricant can also be used to perform other functions in your workspace. You can also save some small pieces of metals and use them in your future projects instead of throwing them away.

4. Look for Proper Waste Disposal Methods

As we have just mentioned, one of the best methods of disposing of the waste is by recycling it. But if the waste cannot be recycled, you should look for an efficient waste disposing method. So, try and find out if your department's waste material can be used in another department and ship them there.

Ensure you install a proper fume management system that can safely and properly get rid of the fumes. You can address the weld fume exposure via process substitution or modification. To protect yourself and your employees, you should change their weld transfer method, use low-manganese filler metals and change the shielding glass. If you have some welding helmets that are no longer used, you can turn them into pots and use them to plant some things in your garden.

5. Virtual Training

Instead of wasting the electricity, raw materials and ending up releasing some fumes into the atmosphere when training new employees, you should use simulators and virtual reality, among other virtual tools. By training your new employees in an environmental-friendly workplace, you will teach them the importance of making sustainable decisions in the future. Teaching new welders in schools or workplaces using virtual means can make them learn how to make eco-friendly decisions throughout their careers.

Final Thoughts

Currently, everyone is moving towards a green economy. We are creating an economy that focuses on lowering ecological scarcity and environmental risk. One of the best ways to achieve sustainable development without degrading our surroundings is by becoming eco-friendly. And since welding plays a key role in infrastructure development and economic progress, it's important that you adopt sustainable welding processes.

And while these practices are considered eco-friendly, it's crucial for your employees to take measures when welding. This includes wearing personal protective equipment to help create a barrier between the workers and dangerous fumes. Some of the common respiratory protections in the market are half masks, disposable respirators, and powered air-purifying respirators.

FAQs

1. Is welding bad for the environment?

As a crucial process in the majority of sectors, welding can considerably contribute to air pollution. All welding activities produce fumes and gases that contribute to the development of air pollution. Due to the high temperature generated during the welding process, several chemicals in the arc evaporate.

2. Which is environmental friendly welding processes?

Diffusive welding is a process that uses pressure and heat to create a solid joint. Because the procedure eliminates the requirement for flux, it is an environmentally sustainable method of welding. Laser gas metal arc welding is another ecologically friendly welding technology. This procedure requires relatively little filler material and also benefits from high speed.

3. Why does nitrogen cause the most serious problems in welding?

Nitrogen in solidified steel reduces the ductility and impact strength of the weld, perhaps resulting in cracking. Nitrogen in excess can potentially result in the formation of weld porosity. Carbon monoxide is produced when the steel's excess oxygen combines with the carbon (CO). Porosity in the metal can be caused by trapped gas.

4. What is the impact of welding?

Welding procedures carry the risk of inhalation exposures, which can result in acute or chronic respiratory illnesses. In addition, asphyxiation from harmful inhalants, skin and eye damage from ultraviolet rays, chemical or electrical fires, and long-term negative consequences from fumes are all possible risks.

5. What is an eco-friendly material?

Eco-friendly building materials cause no harm to the environment during their creation, usage, or disposal and are easily recyclable. Therefore, using environmentally friendly products pays tremendous dividends in the long run.