6 Top Picks

3 Reviewers

16 Hours of Research

15 Products Considered

At A Glance: Our Top Picks for MIG and TIG Welding Gloves

- Lincoln Electric Traditional MIG/Stick Welding Glove Our Top Pick

- Tillman Medium Pearl Top Grain Cowhide Gloves Runner Up

- Tillman 24D Top Grain Pearl Kidskin TIG Glove with 2" Cuff

- Caiman 1878-5 21-Inch One Size Fits All Genuine American Deerskin Welding Glove

- US Forge 403 18-Inch Extra Length Welding Gloves

- Miller 263343 Arc Armor MIG/Stick Welding Glove

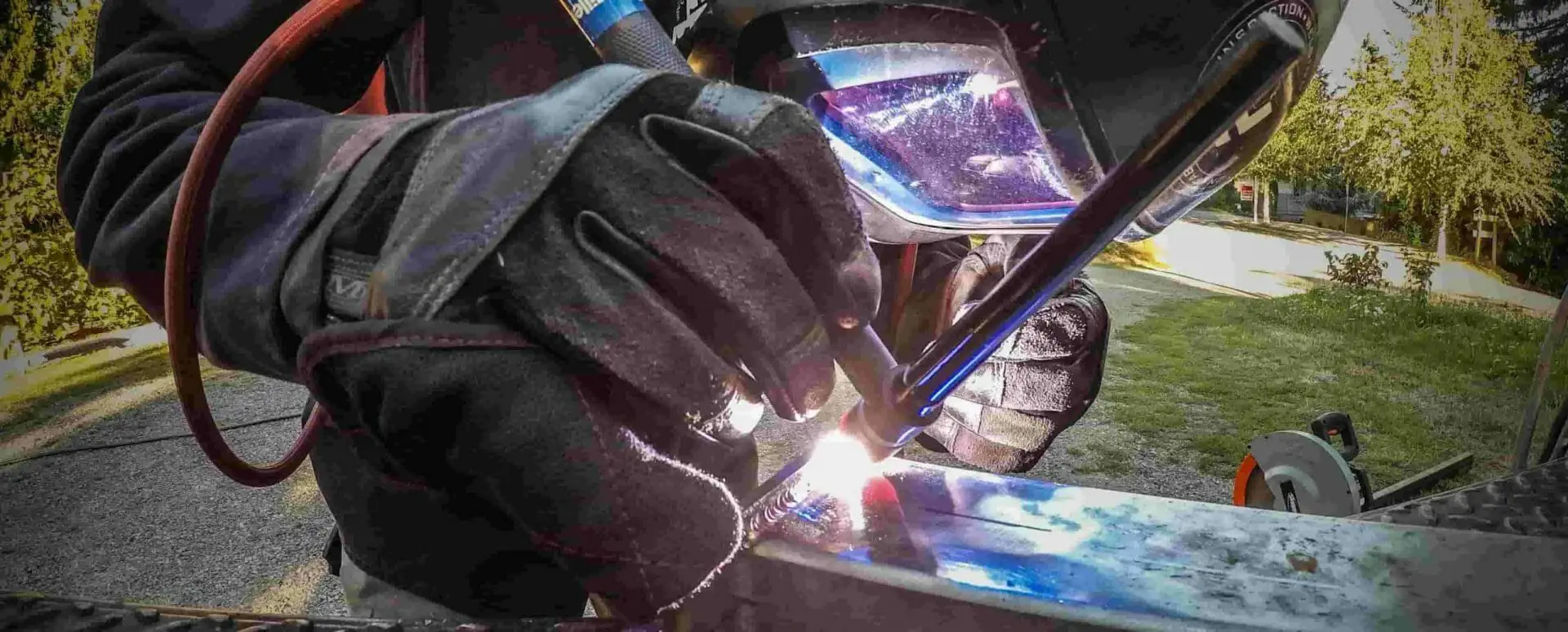

Welding involves a wide range of tasks and a wide range of health and safety hazards. Burns are the most common hazard and injury for a welder due to sparks and molten metal fragments landing on the skin.

Here are some important facts to keep in mind if you are ever tempted to skip proper protection:

Protective Welding safety gear is just as important as the equipment you are welding. The two most important things to protect for a welder are his eyes and hands.

That is why it is essential to wear the proper welding safety gloves and the best welding gloves you can find.

Quick Overview: Our Top Picks for MIG and TIG Welding Gloves

| IMAGE | PRODUCT | FEATURES | |

|---|---|---|---|

|

Our Top Pick

|

|

VIEW LATEST PRICE → |

|

|

VIEW LATEST PRICE → | |

|

|

VIEW LATEST PRICE → | |

|

|

VIEW LATEST PRICE → | |

|

|

VIEW LATEST PRICE → | |

|

|

VIEW LATEST PRICE → |

Last Updated: March 14, 2021

By Gregory Sanders: This article has been updated to reflect the most accurate information regarding welding gloves available for those who are interested in welding protection gear. The best 6 available have changed, and information has been added to assist individuals in finding the best gloves for welding currently available on the market. The FAQ has also been updated.

Reviews of the Best Welding Gloves | TIG and MIG

1. Lincoln Electric Traditional MIG/Stick Welding Glove

Lincoln Electric Traditional MIG/STICK Welding Glove Pros

Lincoln Electric Traditional MIG/STICK Welding Glove Cons

Manufacturer: Lincoln Electric

Weight: 12.2 ounces

Sizes: 13 x 6 x 1 inches, large

Colors: Black and red

2. Tillman Medium Pearl Top Grain Cowhide Gloves

Tillman Medium Pearl Top Grain Cowhide Gloves Pros

Tillman Medium Pearl Top Grain Cowhide Gloves Cons

Manufacturer: John Tillman and CO

Weight: 2 lbs.

Sizes: S, M, L, and XL

Colors: Gold and white

3. Tillman 24D Top Grain Pearl Kidskin TIG Glove with 2" Cuff

Tillman 24d Top Grain Pearl Kidskin TIG Glove With 2" Cuff Pros

Tillman 24d Top Grain Pearl Kidskin TIG Glove With 2" Cuff Cons

Manufacturer: John Tillman and Co

Weight: 1.8 lbs.

Sizes: 6 x 1 x 1 inches, S, M< L<

Colors: White

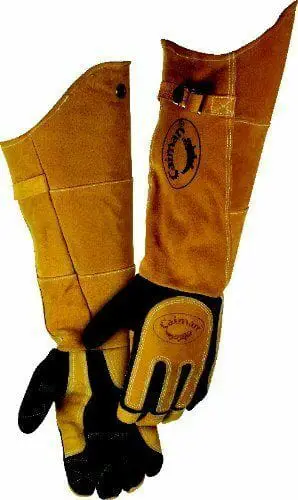

4. Caiman 1878-5 21-Inch One Size Fits All Genuine American Deerskin Welding Glove

Caiman 1878-5 21-Inch Welding Glove Pros

Lots of applications including outdoor use, with wrist bands to help with holding security.

Caiman 1878-5 21-Inch Welding Glove Cons

Manufacturer: Caiman

Weight: 1 lb.

Sizes: 22 x 8 x 12 inches, one size fits all

Colors: Black and gold

5. US Forge 403 18-Inch Extra Length Welding Gloves

US Forge 403 18-Inch Welding Gloves Pros

US Forge 403 18-Inch Welding Gloves Cons

Manufacturer: US Forge

Weight: 3 lbs.

Sizes: 10 x 7 x 2 inches, universal

Colors: Gold and white

6. Miller 263343 Arc Armor MIG/Stick Welding Glove

Miller 263343 Arc Armor MIG/STICK Welding Glove Pros

Miller 263343 Arc Armor MIG/STICK Welding Glove Cons

Manufacturer: Miller

Weight: 10.4 ounces

Sizes: 13.5 x 6.5 x 1 inches S, M, L, and XL

Colors: Black and blue

What To Look For in High Quality Welding Gloves

During welding and cutting operations, having the best welding gloves for the job enhances your welding speed, ability, and safety for a variety of services.

Most employers will make sure welding operators are wearing the best protection for the welding operation in order to reduce injuries and downtime and ensure optimal performance to be the ideal work gloves.

ANSI Z49.11 standards require all welders to wear protective flame-resistant gloves that provide the heat resistance and hand protection needed for welding. They must have the following features:

Just as important is the fit and comfort. If the protection is comfortable, has a good fit and provides the necessary protection, welders are more likely to want to keep it on.

Materials Used for Welding Gloves

The preferred material for welding gloves is leather, to provide the appropriate flexibility and protection from arc rays, molten metal spatter, sparks, and hot metal.

The gloves should be thick enough to not shrivel, burn or get worn out quickly. Various types of leather are used for welding gloves, providing different levels of protection, durability, and comfort.

According to the American Welding Society, the various types of leather provide the following advantages and disadvantages:

Elk Skin

The great level of comfort provided by elk skin does not take away from its heat, flame, and abrasion resistance. It comes in heavier cuts and provides great protection for stick welding.

Cowhide

Cowhide is another durable, heat-resistant, and flame-resistant material for welding at high temperatures.

It is known for versatility, durability, dexterity, abrasion resistance, and comfort. It is common in MiG welding gloves.

Deerskin

The most comfortable fit, along with a lot of dexterity, comes from deerskin welding gloves. Thick deerskin is good for resisting high temperatures, and it provides the advantage of taking the form of your hand over time, which makes it a very comfortable glove option.

Pigskin

Pigskin is highly resistant to both weather and oil. However, it lacks much of the heat resistance provided by other types of gloves.

Goatskin

TIG welders generally prefer goatskin gloves. They are comfortable, light and flexible, which is important for picking up and feeding the filler rods. They are also oil and water resistant.

The best welding gloves are made from top-grain leather, which is the high-quality outer layer of an animal's hide.

Welding gloves balance flexibility with heat protection and will vary depending on the welding process used.

Best Types of Gloves for Different Kinds of Welding

Each kind of welding process requires a specific type of glove appropriate for the job. Knowing what your hands will be exposed to helps you in selecting the best welding glove for each application.

Stick welding creates the high heat and requires stiff, heavy-duty gloves that can withstand high temperatures. The best stick welding glove options include top-grain pigskin, elk skin, or goatskin.

Particular factors in each type of welding mean that gloves also call for special features. For instance, the best MIG welding gloves offer a thick pad at the back of the hand.

This is to protect the hand during a typical position where the non-dominant hand is used to stabilize the welding torch. It creates a stable brace and allows more precise control and the ability to find the plane of workpiece more easily.

To help get the gloves off when they overheat, MIG welding gloves generally fit loosely. The fingers are more rigid, but it’s not a major factor because most of the dexterity required in MIG welding comes from the wrist.

Top-grain cowhide, goatskin, or deerskin are common leather choices you'll find in MIG leather welding gloves.

The best TIG welding gloves are usually made of a softer, thinner leather. At times they may be leather combined with Kevlar or another fire-resistant fabric. Since both palms face the welding tool in TIG welding, there’s no need for the pad on the back of the gloves.

These gloves generally fit more snugly and allow more finger mobility. These design factors allow for the more precise control that TIG welding requires for the torch and filler.

TIG welding produces the least amount of heat but requires precise movement for precise welds with the TIG torch. A lighter and more flexible glove.

Goatskin leather gloves are quite popular and are typically ideal for TIG and MIG welding. However, Deerskin gloves offer the advantage of shaping themselves to a welder's hand over time and make for an extremely comfortable fit.

Conclusion

The whole body must be protected when welding due to the potentially dangerous nature of the craft, and the hands have special safety needs due to their closeness to the welding torch and material being welded.

That’s why it’s so important to have a really protective pair of welding gloves, to keep your hands cool and burn-free while you work so shop today for fast shipping.

FAQs

1. Are MIG gloves good for stick welding?

While some welding gloves are suitable for multiple welding processes, thin TIG gloves are not recommended for stick welding. In addition, some MIG gloves may lack the flexibility required for practical TIG welding.

2. What is the difference between MIG and TIG welding gloves?

The primary distinction between welding gloves is whether they are used for MIG or TIG welding. MIG gloves are typically more relaxed in fit and feature additional padding on the back of the hand. MIG gloves, in general, provide excellent all-around protection for the hand. TIG gloves are made of a significantly lighter, softer material.

3. How long should a pair of welding gloves last?

What is the life expectancy of welding gloves? That is contingent upon several factors. The first is the quality of the gloves, followed by the frequency of use and, finally, the temperature at which you work. Thus, welding gloves typically last between 3 and 12 months.

4. What do welding gloves protect against?

They are designed to safeguard the welder's hands against electrical shock, extreme heat, infrared radiation, and physical cuts. In addition, welding gloves are shockproof because they do not conduct electricity.

5. Can you weld with rubber gloves?

You certainly can. You can also choose from a variety of other materials for your welding gloves. For example, rubber gloves can protect you from electric shocks and moisture. Cotton gloves, on the other hand, can be lightweight and flexible.